An In-Depth Look at Protecting Your Sheet Goods Investment

When it comes to wholesale distribution, ensuring that products reach their destinations in pristine condition is paramount. For wholesalers dealing with sheet goods like plywood, MDF (Medium Density Fiberboard), particleboard, and melamine, protecting these materials from potential damage is critical. This guide explores how plastic angle covers can be instrumental in safeguarding your valuable inventory.

Understanding Sheet Goods and Their Vulnerabilities

Types of Sheet Goods

Common types of sheet goods include:

- Plywood: Known for its strength and versatility, often used in construction and furniture making.

- MDF (Medium Density Fiberboard): A smooth, stable product ideal for detailed work and cabinetry.

- Particleboard: An economical option commonly used for budget-friendly furniture.

- Melamine: Often found in kitchen cabinets and surfaces due to its durable, easy-to-clean coating.

Common Damage Risks

Sheet goods are susceptible to various types of damage, including edge chipping, surface scratching, warping and bending, and moisture absorption. Such damages can compromise the structural integrity and aesthetic appeal of the materials, leading to financial losses and customer dissatisfaction.

Plastic Angle Covers: An Overview

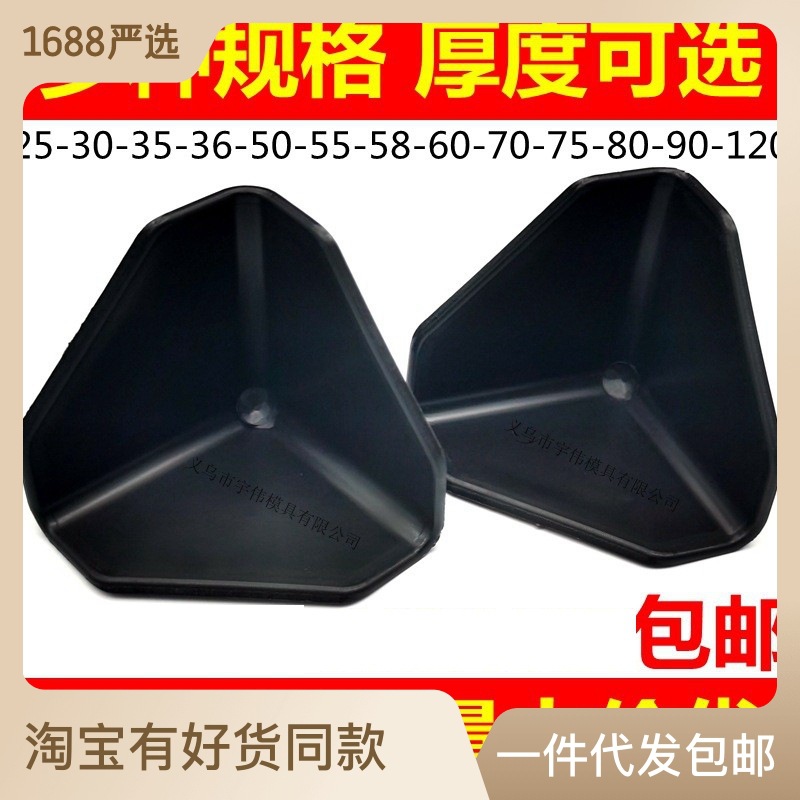

What Are Plastic Angle Covers?

Plastic angle covers are protective elements made from robust plastics. They come in a design that snugly fits over the edges of sheet goods, offering shielded corners against impact and friction during handling and transportation.

Advantages of Using Plastic Angle Covers

The benefits of using plastic angle covers include:

- Durability: Made from high-quality plastics, they offer long-term use and reliable protection.

- Cost-effectiveness: Affordable compared to the cost of possible damage replacements or repairs.

- Reusability: Can be reused multiple times, adding to their economic value.

- Environmental Impact: Reduces waste by minimizing the need for extensive packaging materials.

Selection Criteria for Plastic Angle Covers

Material Strength and Flexibility

Selecting the right type involves comparing different plastics like PVC and PE for their toughness and flexibility. It's crucial to assess the impact resistance suitable for your specific sheet goods.

Size and Fit

Choosing between standard sizes and custom sizing options ensures that each piece fits securely on varying thicknesses of sheet goods.

Compatibility with Various Sheet Goods

Ensuring a snug fit around the edges while allowing adjustments for thickness variations will provide effective protection across all types of sheet goods.

Best Practices for Application

Pre-Installation Inspection

Before applying plastic angle covers, check for any existing damages on the sheet goods. Ensure that the edges are clean and free from debris to maximize adhesive effectiveness and protection.

Correct Placement Techniques

Align the covers accurately along the edges and secure them using additional materials such as straps or tape if necessary to maintain position during transit.

Leveraging Additional Protective Materials

Consider combining corner protectors with other protective methods like shrink wrapping or palletizing for enhanced security.

Packaging Strategies for Wholesalers

Bulk Packaging Solutions

Palletizing multiple sheets together and using interleaving materials can prevent movement and abrasion between pieces during shipment.

Custom Packaging Options

Tailor packaging solutions for high-value products, integrating sustainable packaging innovations where possible.

Labeling and Documentation

Clearly mark fragile items and include detailed handling instructions to guide transporters during the shipping process.

Transportation Considerations

Loading and Unloading Procedures

Use appropriate equipment like forklifts to handle sheet goods, reducing manual handling which can lead to damage.

Securing Goods in Transit

Apply strapping and bracing techniques to secure sheet goods and continuously monitor for movement throughout transit to mitigate risks.

Cost Analysis and ROI

Initial Investment vs. Long-Term Savings

While there is an initial investment in purchasing plastic angle covers, the reduction in loss and damage costs results in substantial long-term savings, as evidenced by real-world case studies.

Case Studies and Success Stories

Many wholesalers who adopted plastic angle covers have reported significant drops in damaged goods, underscoring their return on investment.

Supplier Selection and Procurement Tips

Choosing a Reliable Supplier

Select a supplier known for quality and consistency. Research reviews and reputation to ensure you receive dependable products.

Negotiating Bulk Purchase Agreements

Effective negotiation strategies can yield cost-effective bulk buying and understanding delivery schedules will streamline your procurement process.

Quality Assurance Practices

Regular audits and feedback loops with suppliers ensure ongoing product quality, enhancing overall satisfaction and reliability.

Future Trends in Sheet Goods Protection

Innovations in Protective Materials

Advances in plastic technology and eco-friendly alternatives are emerging, providing improved sustainability without compromising protection.

Automation and Smart Packaging

The integration of automation and IoT technology into packaging processes offers new potentials for monitoring and managing shipments more efficiently.

Additional Resources and Further Reading

Industry Standards and Guidelines

Diving into relevant industry standards helps understand regulatory considerations necessary for compliance and optimal protection techniques.

Educational Materials and Workshops

Engage with webinars, seminars, and recommended readings to stay updated on best practices and innovations in packaging and protection.

Adopting comprehensive steps to protect sheet goods through measures like plastic angle covers not only safeguards your investments but also elevates your service quality, instilling greater confidence among customers and partners alike.